Canned Motor Pump Services

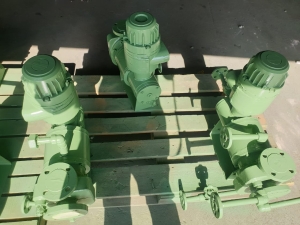

CANNED MOTOR PUMPS:

With no mechanical seal and external lubrication or, any possibility of misalignment with driver, our pumps are built for reliable and long trouble free Operation. With proper installation/commissioning and with due monitoring/protection for abnormal operating conditions, our pumps require minimum maintenance. With timely replacement of wear parts and preventive maintenance, long mean times between failures (MTBF) can be ensured. Nevertheless, major maintenance when required, needs to be done with proper procedures to refurbish the pump to the original condition.

Our range of services are focused on extending of support in each of the above area, thereby reducing the total cost of ownership of our pumps to Customers. We offer following services with this objective:

On-site Assistance:

We depute our Service Engineer / Supervisor to your facility for on-site supervision during installation/commissioning, trouble shooting and field maintenance.

Repairs & Refurbishing

We have experience, expertise, staff, and facilities to repair and refurbish CMPs after major event such as damaged stator/rotor. Our expert technicians will inspect the damage and provide you with assessment report on damaged parts and scope of repairs required.

Upgrades & Rerates We leverage our design and manufacturing expertise in meeting challenges of redesigning of existing pumps and meet following objectives of our customers:

- Upgrade conventional pump with mechanical seal to seal less technology.

- Rerate existing pump for revised service conditions.

- Upgrade existing pump to overcome the root cause for short MTBF experienced.

- We undertake repairs, maintenance & dynamic testing of Canned Motor Pumps & other conventional pumps of any make & brand.

- Maintaining AMC related to spares & carrying out repairs for Canned Motor Seal less Pumps for us or any other brand such as Nikkiso, Teikoku, Hermetic, KSB etc.

- Supplying & fabrication of spares related to other conventional pumps.

- Designing & supplying New Canned Motor Pump as per process requirements.

A MODERN PUMP

FOR A NEW MILLENNIUM

Safety Meets Efficiency

The ever-increasing demand for environmental safety at a reasonable cost presents a unique challenge to the Process Industries: find and utilize equipment that, while operating leak-free, performs reliably and efficiently. Teikoku's Canned Motor Pump more than meets the challenge.

Besides double containment for coral fluid control, the pump offers some remarkable performance advantages. Designed to enable long periods of time between maintenance (with pre-planned downtime) , it has only a few components that need to be monitored and serviced. lt never requires costly alignment procedures or external lubrication. And , because it is seal less, The Teikoku Canned Motor Pump eliminates seal maintenance as well as the demands of complicated seal support systems.

The Teikoku Canned Motor Pump: true secondary containment, reliable operation , cost-efficiency...and continuing environmental concern.

ADVANTAGES OF

CANNED MOTOR PUMB

NO LEAKAGE

Handles toxic explosive, expensive, hazardous , carcinogenic and corrosive fluids without leaking.

COMPACT DESIGN

Motor and pump are a single unit. No alignment is necessary. No grouting or elaborate is needed.

AIRTIGHT

Ideal for vacuum services or for fluids that react to contact with air.

QUIET OPERATION

Low noise level since no fan is used to cool motor. All rotating parts are within a thick shell Container.

NO SHAFI SEAL

No mechanical seal. No gland packing.

NO EXTERNAL LUBRICATION

Pumped fluid provides cooling and lubrication of motor and bearings. No lubrication levels to check or maintain.

VACUUM to HIGH SYSTEM PRESSURE

Rated to handle conditions from full vacuum to 5,000 psi/ 35 MPa.

EXPLOSION PROOF

Certified by TIIS (Japan), PTB (Germany) and many other authorities

API 610 NOZZLE LOADS

FIELD REPAIRABLE

All wear parts arc easily changed

ANSI SIZES & 1502858 SIZES AVAILABLE

ALL PUMPS PERFORMANCE TESTED

Every component of each pump is manufactured by Teikoku adhering to strict statistical quality control tolerances, and each pump and motor arc 100% performance-tested before shipment.

BASIC VERSIONS

F-V TYPE (BASIC TYPE WITH HOLLOW SHAFT)

Fundamental design of TEIKOKU Motor Pump. Most commonly used for a wide variety of applications.

XG TYPE (GAS- SEALEDSLURRY TYPE)

Handles fluid with considerable slurry. Besides XG- type, SG-type with external flushing is also available.

K-S TYPE (FULL-STEAM-JACKET TYPE)

Suitable for handling fluids with high melting points.

X TYPE (HIGH-TEMPERATIRE-INSULATION TYPES)

Suitable for handling high temperature fluids, such as heat transfer oil.

R TYPE (REVERSE CIRCULATION TYPE)

Suitable for handling volatile fluids, such as Ammonia, Freon, and other liquified gases, and for low NPSH applications.

F-M TYPE (MULTI-STAGE TYPE)

Higher head, higher efficiency pump. Besides F-M type, R-M (Reverse Circulation) type and B-M (High Temp-Insulation) type are also available.

SOLUTIONS

SOLUTIONS